PVC Purge Vs Competition

Cleaning Degraded PVC on 100 Tonnes Injection Moulding Machine

The Process

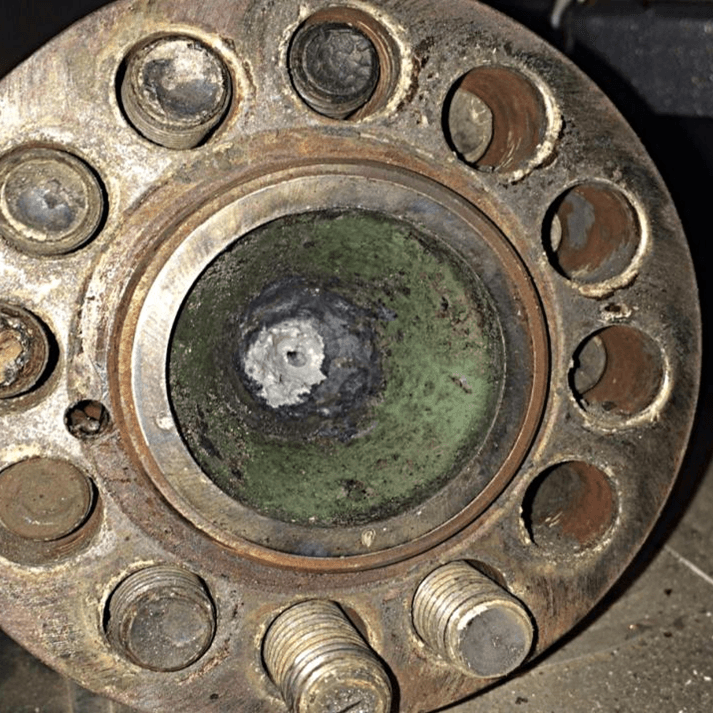

Degradation left in end cap using

competitor’s product

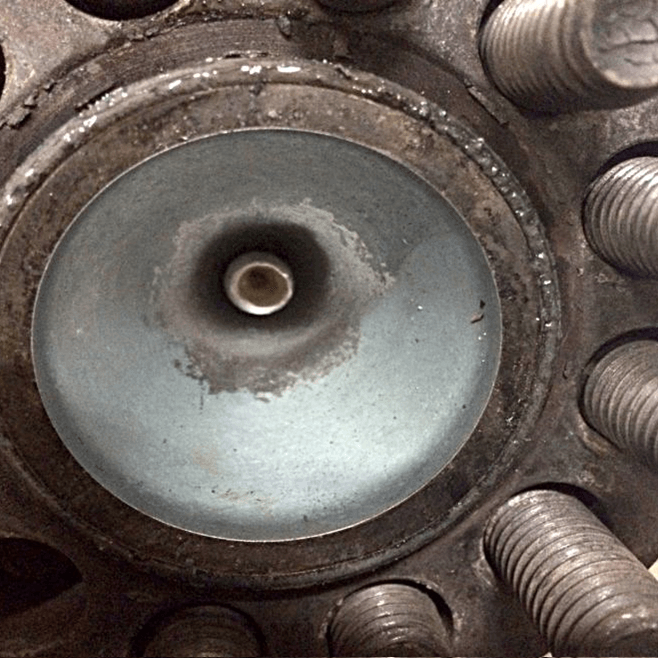

End cap after using

PVC Purge

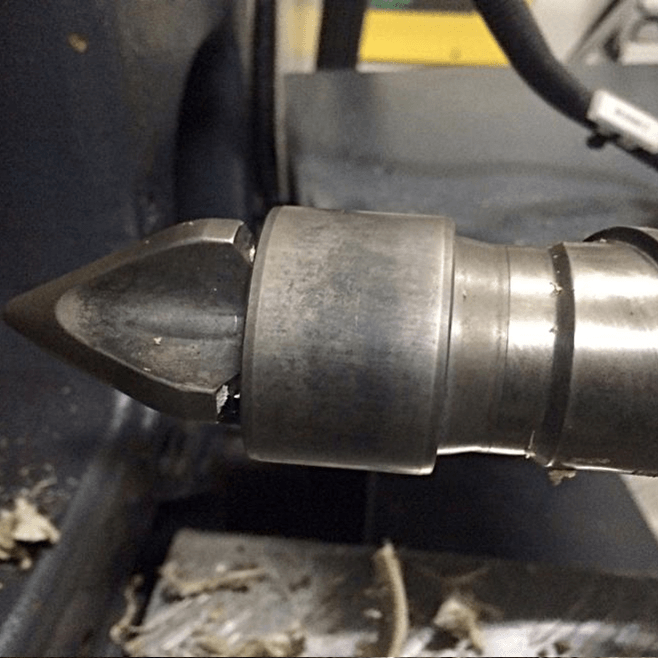

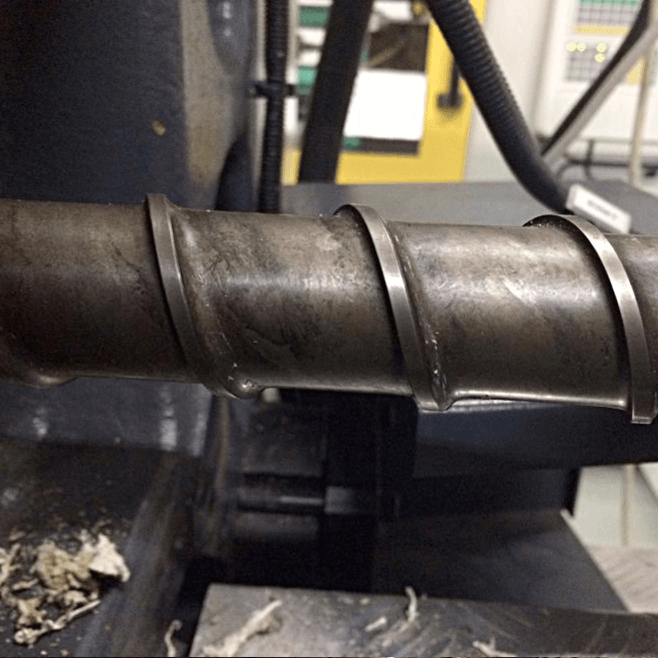

Degradation left on end of screw tip using competitor’s product

Screw tip after using

PVC Purge

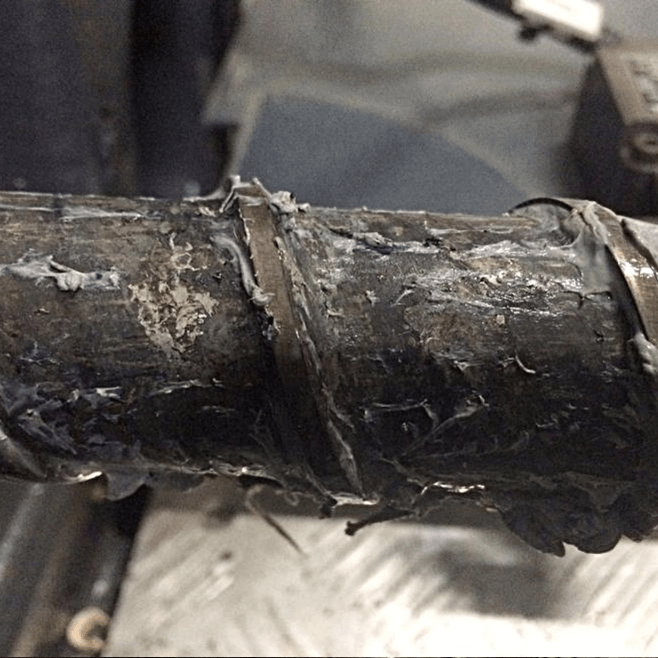

Degradation left on metering section using competitor’s purge

Front section after using

PVC Purge

Degradation left in middle section using competitor’s purge

Middle section after using

PVC Purge

Results

Normal results:

- 5 kg of competitor’s purge

- 15% rejects

- Typically pull & clean screw (3 hours)

Aquapurge results:

- 2 kg of PVC Purge in 10 min

- Screw tip and screw spotless

- Production run 0.1% scrap

You can also read this Case Study here

Request a free demo

Fill in the form and we will send you a free demo to test our product