PVC Purge Vs Competition

Cleaning Degraded PVC on 100 Tonnes Injection Moulding Machine

The Process

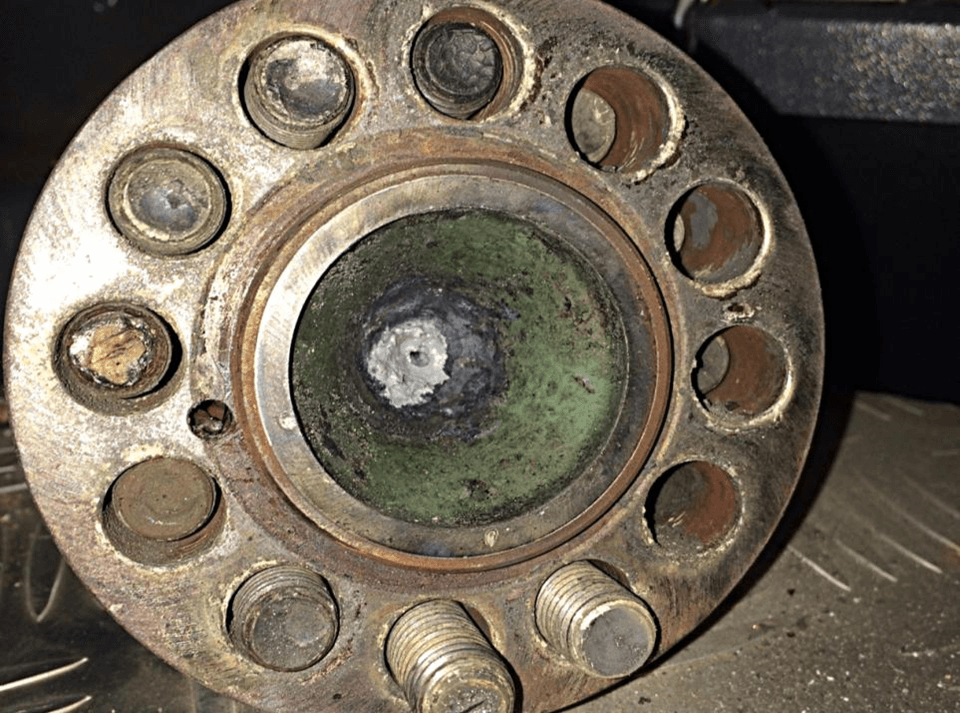

Degradation left in end cap using competitor’s product

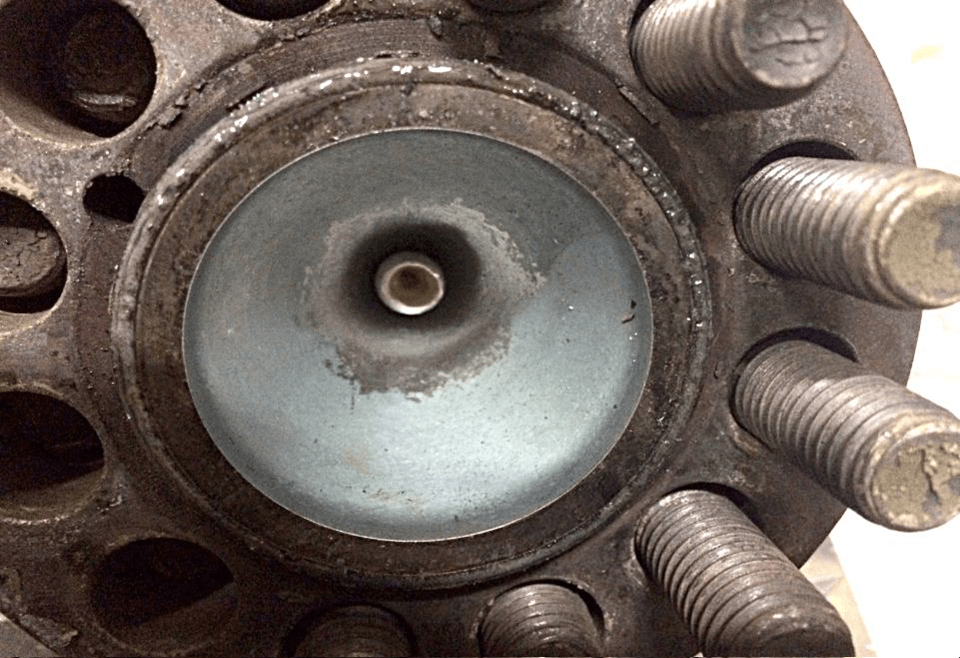

End cap after using PVC Purge

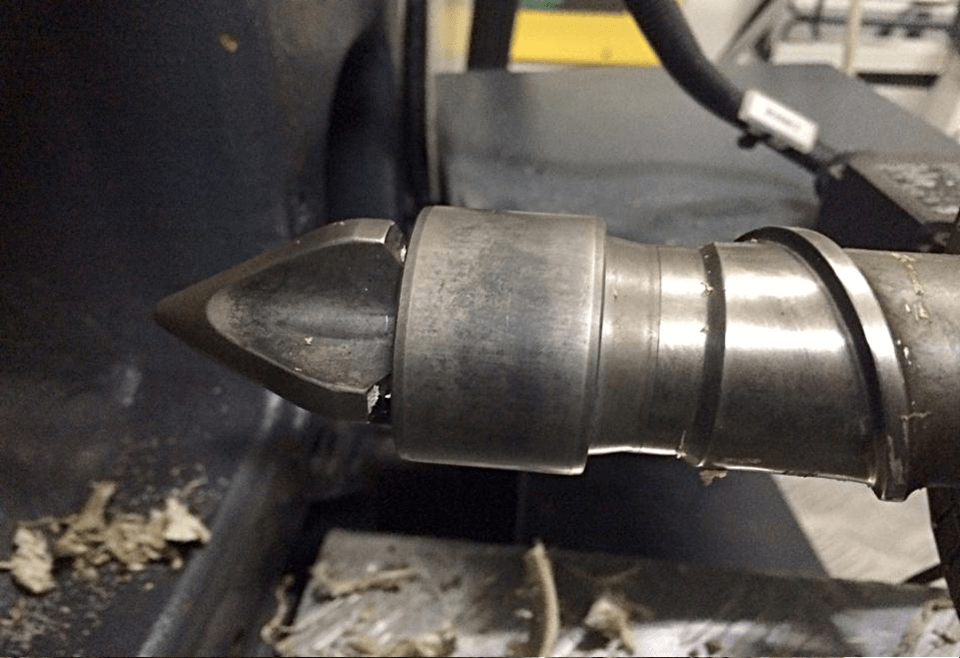

Degradation left on end of screw tip using competitor’s product

Screw tip after using PVC Purge

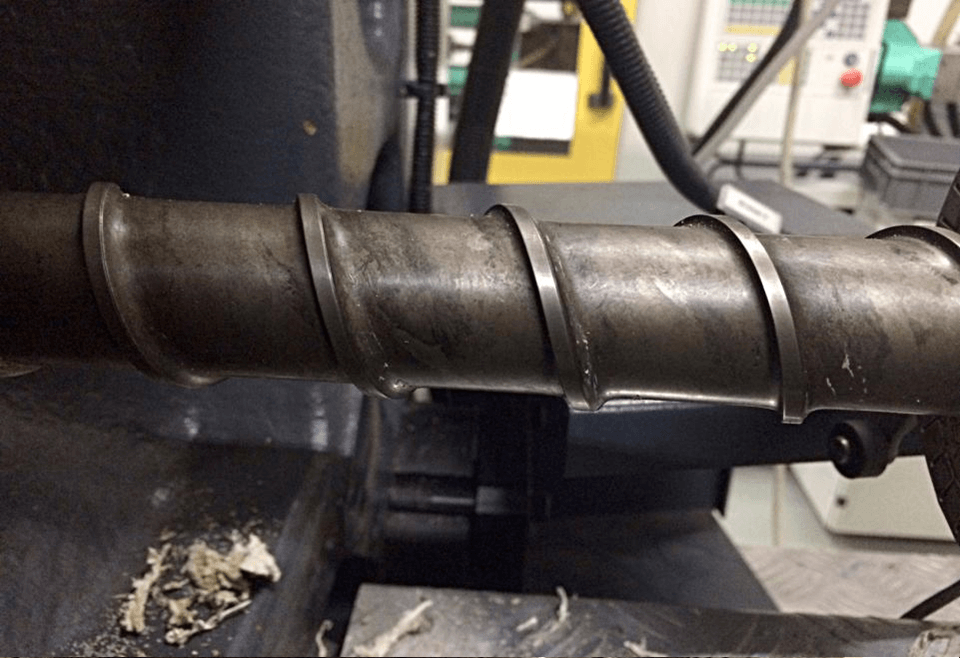

Degradation left on metering section using competitor’s purge

Front section after using PVC Purge

Degradation left in middle section using competitor’s purge

Middle section after using PVC Purge

Results

Normal results:

- Purge 3 kg of competitor’s product + PVC

- Strip/clean M/c weekly

- 3 hours time lost

Aquapurge results:

- 1.5 kg PVC Purge

- 10 mins purging

- No need to strip/clean