Product description

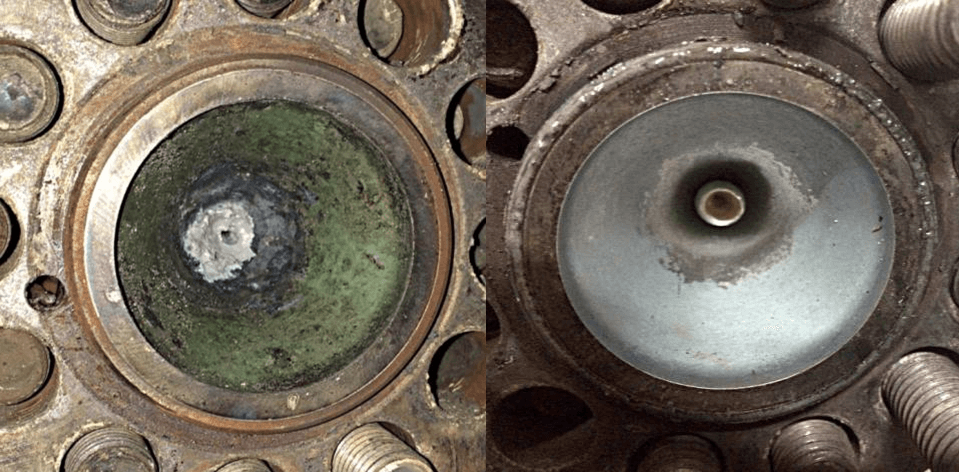

PVC Purge shifts stubborn carbon deposits from extrusion, injection moulding and blow moulding machinery that is processing PVC. It achieves this using a fully mechanical scrubbing action.

The degradation process of PVC materials is typically through shear and heat. This is compounded by the autocatalytic effect caused by hydrochlorination. This is from the hydrochloric acid which is expelled during the degradation process causing the PVC material to further degrade.

However, PVC Purge when used regularly – and even just the first time – succeeds in mechanically removing all the carbon from your equipment.

Although most historical PVC bottle makers have changed to other polymer solutions, there are still companies producing PVC bottles that continue to strip down their machinery. This time-consuming and expensive process can be consigned to history by using PVC Purge.

This same rationale applies to injection moulders who are having to pull and clean their injection screws on a regular basis. Instead, PVC Purge can automatically clean your moulding equipment; eliminating the need for an expensive and time-consuming manual strip-down.